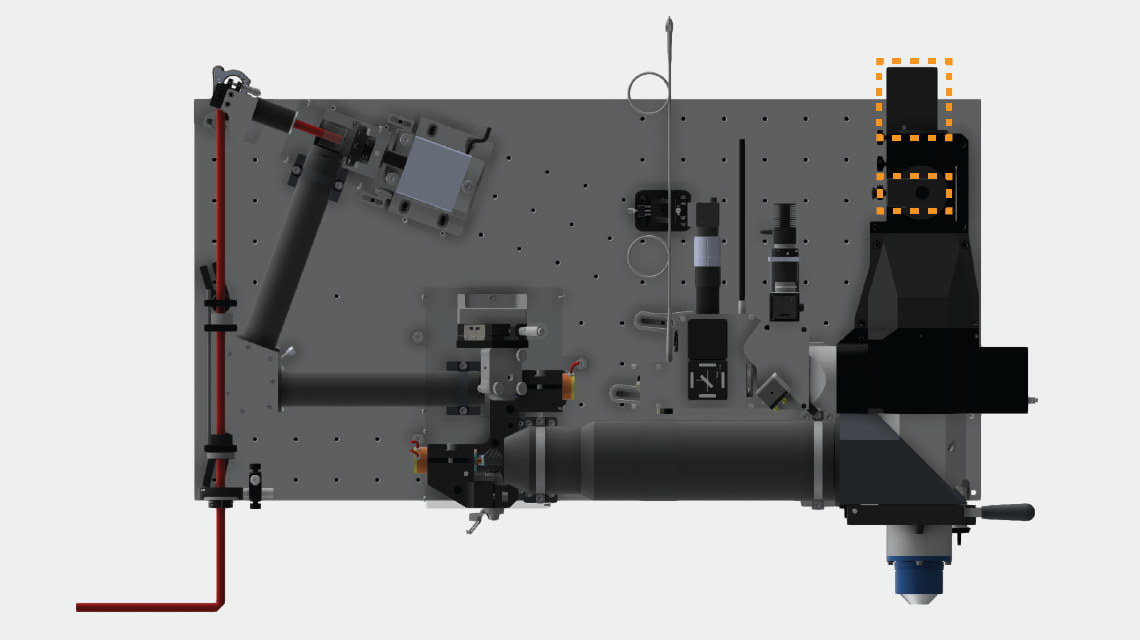

Model labels: DetChannelAssby:1, DetChannelAssby:2

Assembly instructions

Oil method

...

UV cement method

Note: applying UV light to cure UV cement will not harm the PMT photocathode. There have been problems when using UV cement with thick layers of cement (few hundred micron), resulting in permanent bubbles present between the lens and PMT, but the strategy below should not have such problems. It is currently untested, however.

A relatively foolproof way to do the PMT condenser lens bonding with UV cement would be to fill the gap between the condenser lens (flat, optical surface) and the PMT window with another piece of glass (index of refraction ~1.5), and then only use thin UV cement layers, like when bonding a doublet lens, between all the glass pieces. Pieces of coverglass would work fine for this. It would just be necessary to find the right thickness of the gap-filling glass, such that there aren't any air gaps, and the condenser lens doesn't have to rise up much beyond its normal seating position (shoulder touching the PMT housing). Two to three #1.5 coverglass pieces ought to do it. After assembling everything dry to test the thickness and fit of the filler, the filler pieces could be cemented to the condenser lens first, and then whole assembly would be cemented to the PMT.