SECTION 1: INITIAL MODULE ASSMBLEY

These modules should be assembled on a bench before mounting on the vertical breadboard. Assembly of the modules can be done in any order.

Entrance beam expander: EntranceBeamExpander_4x1

1) Mount the Thor_ACN254-050-B:1 lens in its lens tubes ensuring that its curved sides will point inwards when assembled.

2) Assemble the cage from thorlab parts including Thor_AC254-200-B-ML mounted lens. Set the lens cage plates approximately 141mm apart. The exact position of the plates will be set during microscope assembly.

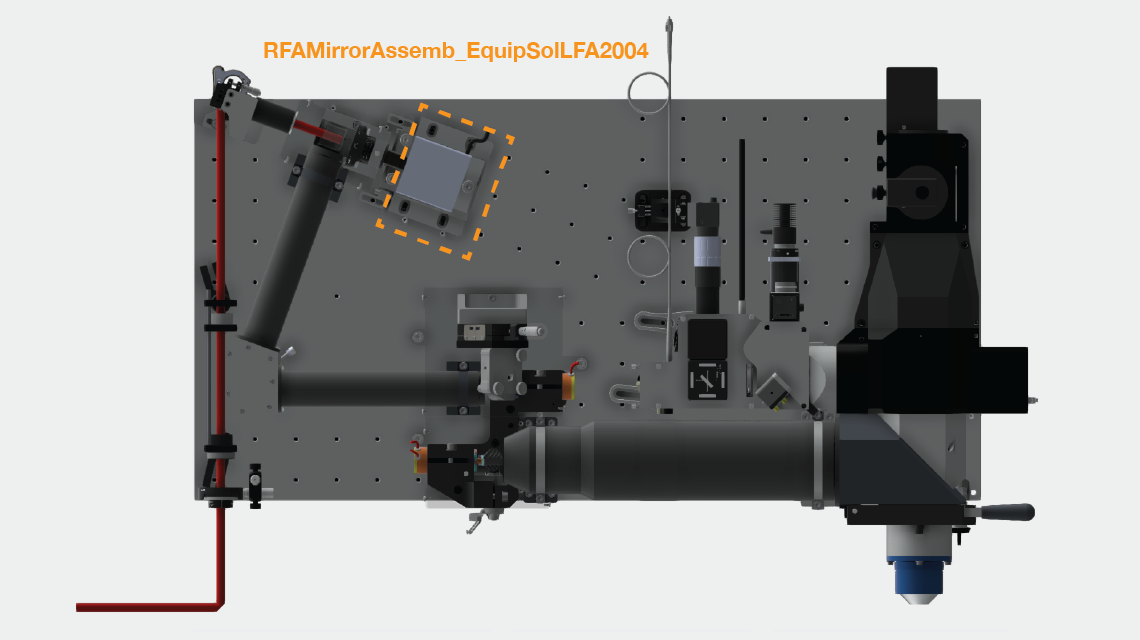

Remote focus mirror positioner: RFAMirrorAssemb_EquipSolLFA2004

1) Gather parts for mounting the mirror on the voice coil bobbin. Clean the mirror mounting screw 90666A101_TYPE 316 SS LOW PROFILE SOCKET HEAD CAP SCREW with drop of methanol. Place small drop (30 ul) of lock-tight onto threads on the voice coil bobbin. Screw in screw, and leave overnight to set.

2) Glue remote focus mirror onto the screw using 1-day epoxy. Fill hole on top of screw with epoxy and then mount mirror centered on the screw head (slight deviations from the center of the screw head are fine).

3) Assemble the voice coil base and mount voice coil

***INSERT PHOTO OF FINISHED ASSEMBLY***

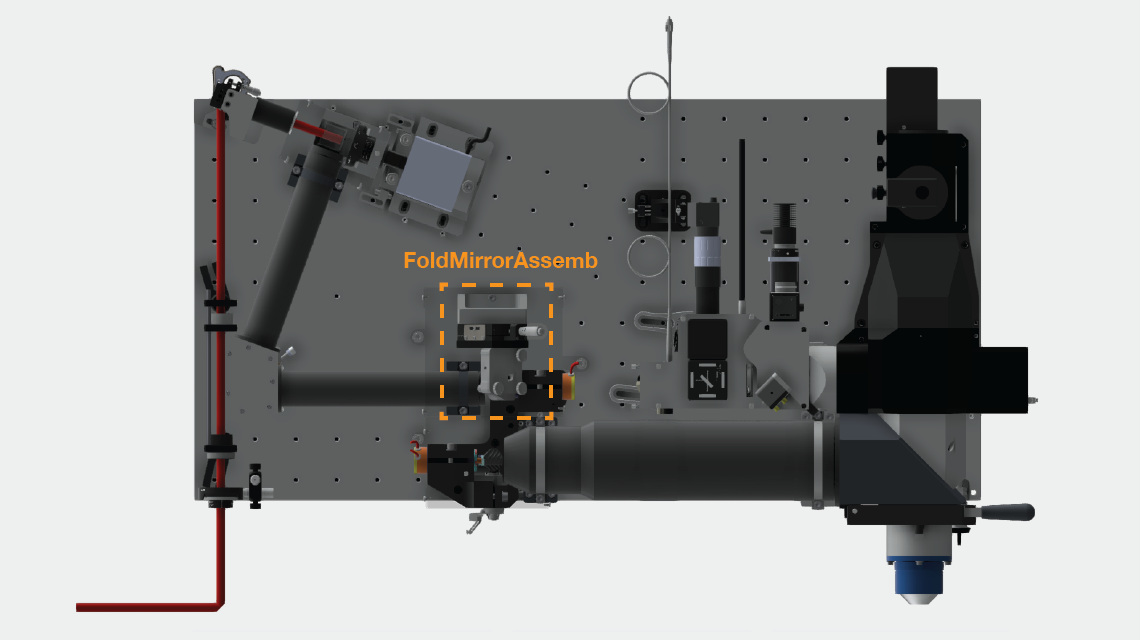

Fold mirror assembly: FoldMirrorAssemb

1) Attach translation stage to the FoldMirrAssembBracket.

2) Attach McMassterCarr standoff to FoldMirrAssembBracket

3) Attach gimbal mount to translation stage via adaptor plate.4) Adjust thickness of gimbal mount to 29.7 mm. The knob in the bottom corner should no longer be adjusted. Mark it with a red X to ensure it doesn't accidentally get changed during the setting of the compensators.

***INSERT PHOTO OF RED X on gimbal***

5) Cement the fold mirror to the gimbal.

***Describe gluing procedure ***

***INSERT PHOTO OF FINISHED ASSEMBLY***

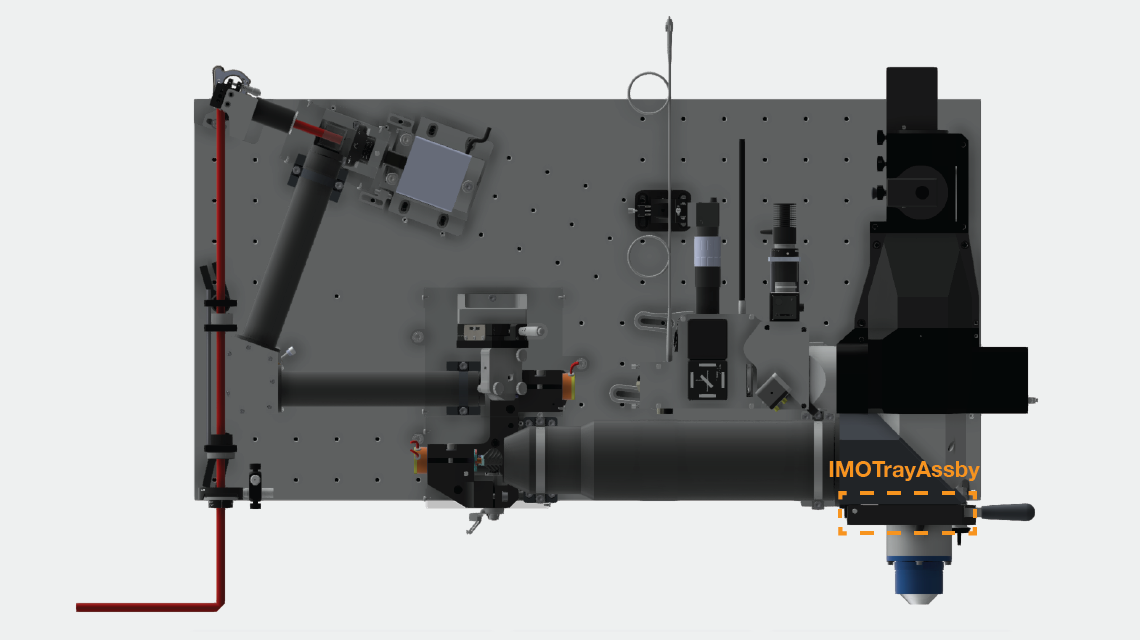

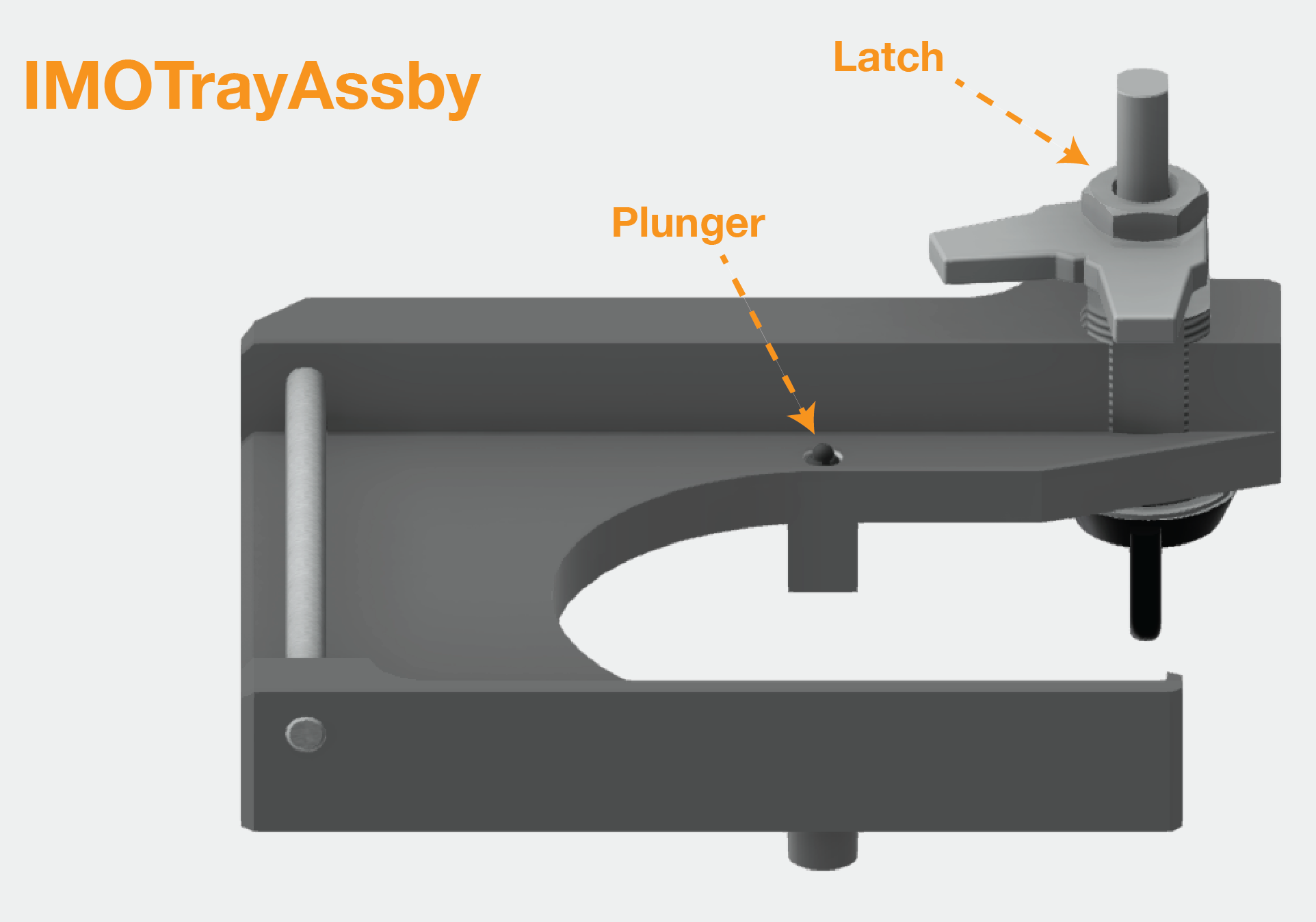

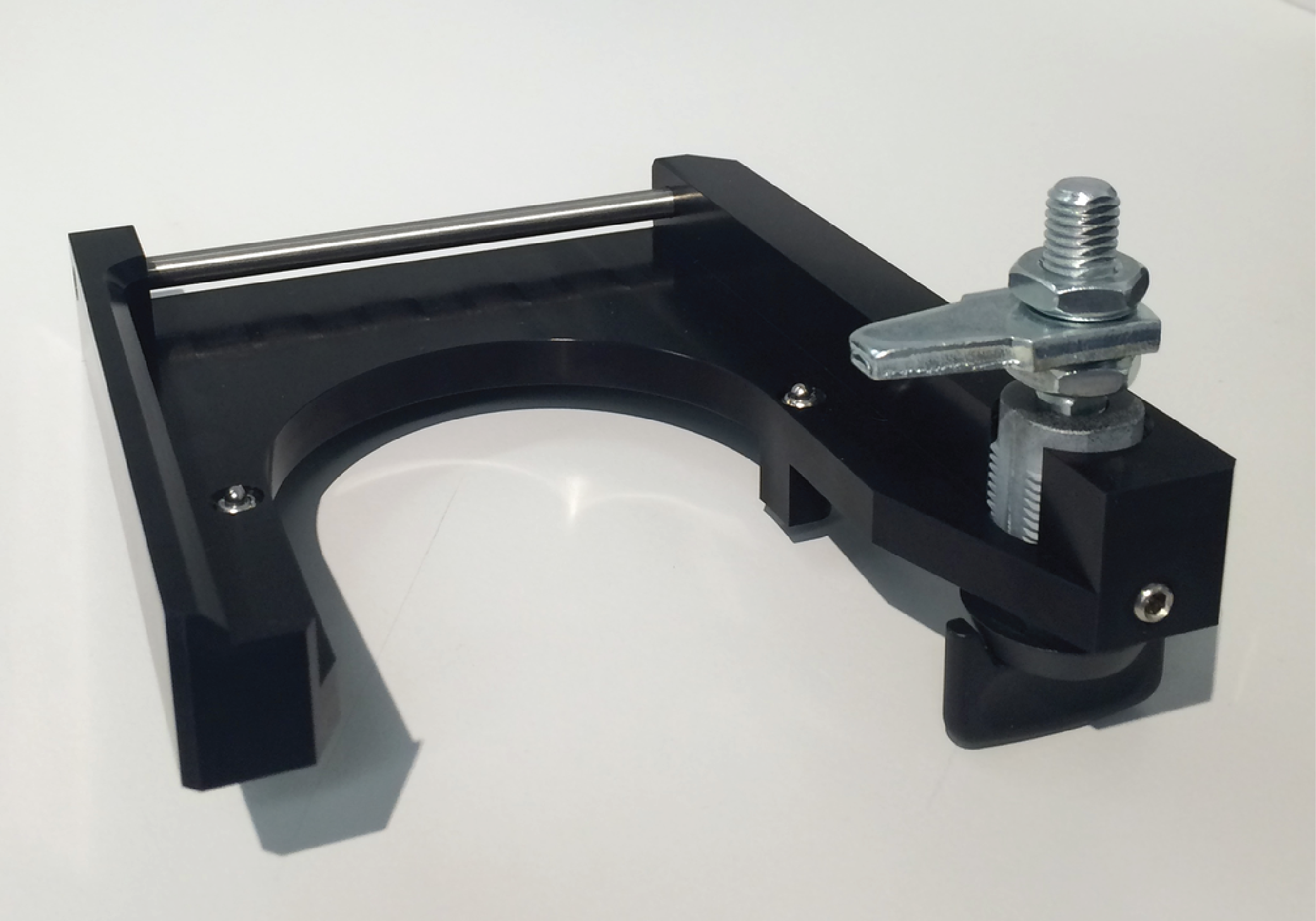

Imaging objective tray: IMOTrayAssby

1) Set to of plunger to be flush with the metal surface of the tray

2) Slide dowel rod in place

3) Assemble latch, making sure orientation is correct when the latch is fully closed and open. The exact height of the latch will be set during final assembly.

Big detection lens and accessory optics dichroic holder: BigDetLensHolderAssby

DichroMotorBaseAssby

Assembling base plate, screw in bearings, make sure balls do not fall out of carridge

Glue magnets into base plate - make sure poles face in same direction **** INCLUDE PHOTO ***

Glue in rack with 5 min epoxy, push down hard so flush

MovingDichroAssby

Assembling slider & carriage

Motor assembly

Solder motor wires to carriage connector

Mounting of accessory dichoric / mirror (gluing to spider)

BigDetLensHolderOnlyAssby

Mounting slider in holder

Mounting lenses (big collection lens and accessory tube lenses)

MotorizedMirrorCoverAssby

Assemble slider cover

Emission splitting dichroic assembly: EmissSplitDichroAssby

EntranceQtrWavePlateAssby

1) Position the post 4" post such that its top surface is 22 mm from the top surface of the RA90, and position the 1.5" post such that it is back surface 15 mm from the back surface of the RA90.

2) Attach the the rotation slider and the quarter waveplate.

Assembling compressor

Assemble the retroreflector carriage

1) Mount the AP90RL large angle bracket on the XT95P11 carriage.

2) Attach the TSX-1D stage to the AP90RL large angle bracket.

3) Use two M6 12mm screws to attach Thor_BA2F to retroreflector.

4) Attach the RS1:4 to the TSX-1D stage with a set screw.

5) Slide the BA2F onto the RS1:4. Adjust the orientation such that when the beam enters the retroreflector it will be reflected up without hitting an edge.

Assemble the 2x beam expander

1) Attach the SM1D12D ring iris to the GBE02-B 2x beam expander, making sure it is on the correct end.

2) Attach the SM1RC lens tube rings to the TR-05:4 posts and put them in the UPH3 universal post holders.

3) Slide the beam expander into the lens tube rings and tighten them

Assemble the prism pair compressor

Use norland 81 UV cure glue.

1) Glue prisms to TRT3 post with cutout. First glue the bottom prism, flush to the top surface of the post cutout, and positioned at a right angle. Put a few drops of UV cure glue on post and place prism on top. Do this inside a V-block to ensure the angles are correct. Once the bottom prism has been glued down, glue to top prism at a distance of 39.3mm (between outside faces). Then glue mirrors to prisms. Hold post in vice at correct orientation, place UV cure glue on prism and glue down mirror. Rotate post to glue second mirror.

2) Glue mirror and prism to polaris mirror mount, making sure orientation is correct. Attach this mirror mount to the top of the KB1X1 kinematic mount using a 8-32 screw and a nut.

3) Glue two mirrors and prisms to polaris mount and centering plate. First attach KCP2 centering plate to polaris mount. Glue one prism directly to the mount, then glue one prism to the the side of the centering plate. Leave a 1 mm space between the two prisms, and a 1 mm gap between the back face of the prism and the mount. Make sure the side of the prisms are both aligned to each other and the side of the polaris mount.

4) Attach the TRT3 post of the top plate of the KB1X1 kinematic mount using an AE8E25E internal to external thread adapter. The length of the external thread adapter needs to be shortened by about two threads to let it fit inside the TRT3 post.

5) Attach one polaris mount to the RM1F cube. Attach this cube with the RS2M spacer to the BA2 baseplate, making sure the cube is orientated such that the corner of the polaris mount is over the center of the BA2. Attach the BA2 to the Optosigma rotation stage, sliding the BA2 so the end of the slots is flush against the screws.

6) Secure the optosigma to the breadboard such that it is 25.3 mm from right side and 2.5 mm from top side.

7) Secure posts with polaris mounts to breadboard, matching the location of the items with their approximate locations in the breadboard. Ensure that the mirror, prisms all lie on the same axis.

8) Set the height of the KMCP to be 46.0 mm above the breadboard.

9) Glue custom prism onto polaris mount. Use norland 81. There are two polished and one un-polished side. Note prism is not an equilateral triangle. Make one side flush with polaris mount, and tip flush with other edge of mount.

10) Set the height of top of the iris holding posts to 87.0 mm

BeamPeriscopeAssby_2AxisStages_Solid

1) Glue a right angle mirror MRA20-P01 to polaris mount using norland 81, making side flush to bottom of mount and front flush to top of mount.

2) Glue a right angle mirror MRA20-P01 5.1 mm from edge with dial, and flush with the back of the stage.

3) Attach stages to the SolidPeriscopeBase, and attach the polaris mount to one of the stages in the correct orientation.

4) Remove redundant knob on polaris mount, as it should not be adjusted

Resonant mirror assembly: ResMirrChamber

1) Screw in schneeberger slider from underneath, make sure to use the correct 10 mm long screws so as not to damage stage

2) Add the stop screw, spring plunger, and threaded bushing (remove the lock screw) and lock nut, knob, and screw for positioning the stage.

3) Glue in the CRS resonant mirror cable using a black RTV sealant (Dow-Corning 732 multipurpose sealant), leaving 7" outside of the chamber. Let the glue cure overnight.

4) Align the resonant scanner inside its mount. UV cure a mirror to the resonant mirror alignment jig. Slide the body of the resonant scanner inside its mount and then attach the mount to the alignment jig. Adjust the height of the resonant scanner such that the center of the mirror is aligned with the top surface of the alignment jig. Rotate the resonant scanner such that its mirror is at the same angle as the alignment mirror. This angle can be determined by shining a laser beam at both mirrors simultaneously and rotating the resonant scanner inside its mount until the reflect beams are parallel.

Resonant mirror alignment in alignment jig (before moving the mirror into the chamber)

The alignment jig has a mirror mounted on it – this is a reference point for the orientation of the resonant mirror.

An alignment laser should hit the resonant mirror and the alignment mirror at the same time.

Adjust the orientation of the resonant mirror carefully so that the two reflections overlap.

Height of the top edge of the resonant mirror should be 2.7 mm.

Virtually conjugate galvo-galvo pair

Build alignment jig

Mount galvo mirrors on shafts

Setup alignment laser

Wire up and turn on galvos

Do alignment

XXXXX Prepare V-blocks — insert photo of parts with screws

IMOHolderAssemb

1) Add

Imaging objective mounting

Assemble imaging objective mount

Gluing kinematic mount

Assembling primary dichroic cap

Putting in spring plungers and set screws

Emission splitting dichroic assembly

PMT assembly

Assemble alignment jigs

Alignment jig cage assembly

Imaging objective alignment jig mount

QQQQQ Creating the remote focus objective assembly

Gluing the polarizing beam splitter to the remote focus objective assembly

Mounting the quarter waveplate

Mounting the remote focus objective

Assembling the covers

Assembling objetive mounted optic holder

Accessory optics

1) Remove galvo mirrors from mount

Mounting galvo driver and resonant driver boards (Spencer / Steve documentation)

Making samples

Beads

Fluorescein

Accessory optics

SECTION 2: MOUNT ON BREADBOARD

Mounting on the breadboard

SECTION 3: WIRING

Set up scanimage

Machine data file setting

Wiring galvos / voice coil / PMTs / etc.

SECTION 4: TABLE OPTICS ALIGNMENT

Initial table optics

Pockels cell

Shutter

2x table beam expander

Assembling the compressor

Build enclosure for table optics

SECTION 5: MICROSCOPE ALIGNMENT

Multistage periscope alignment

Quarter wave plate adjustment for multistage periscope

Alignment of beam to remote focus objective

Adjustment of quarter wave plates for maximum transmission

Alignment of RF mirror assembly

Alignment of beam to imaging objective using compensators

Adjustment of galvo voltage divider gain

SECTION 6: IMAGING

Dye pool imaging to set compensators

Dye pool imaging to set retroreflector position

Image beads and measure PSF

APPENDIX A:

Accessory optical path

Assembly, alignment, calibration, adjustment