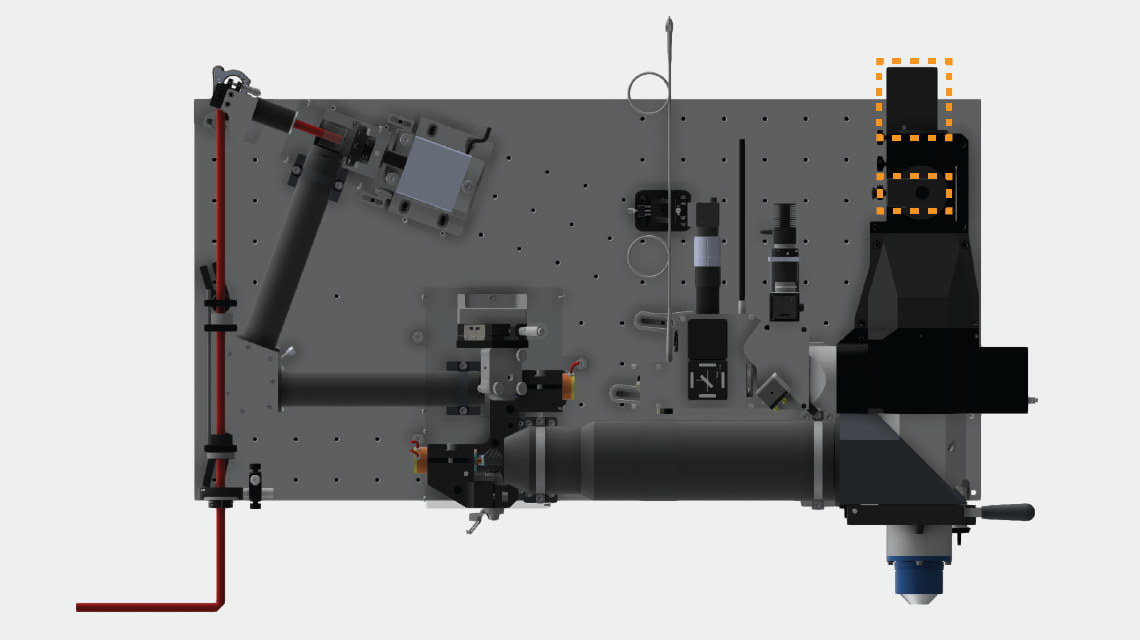

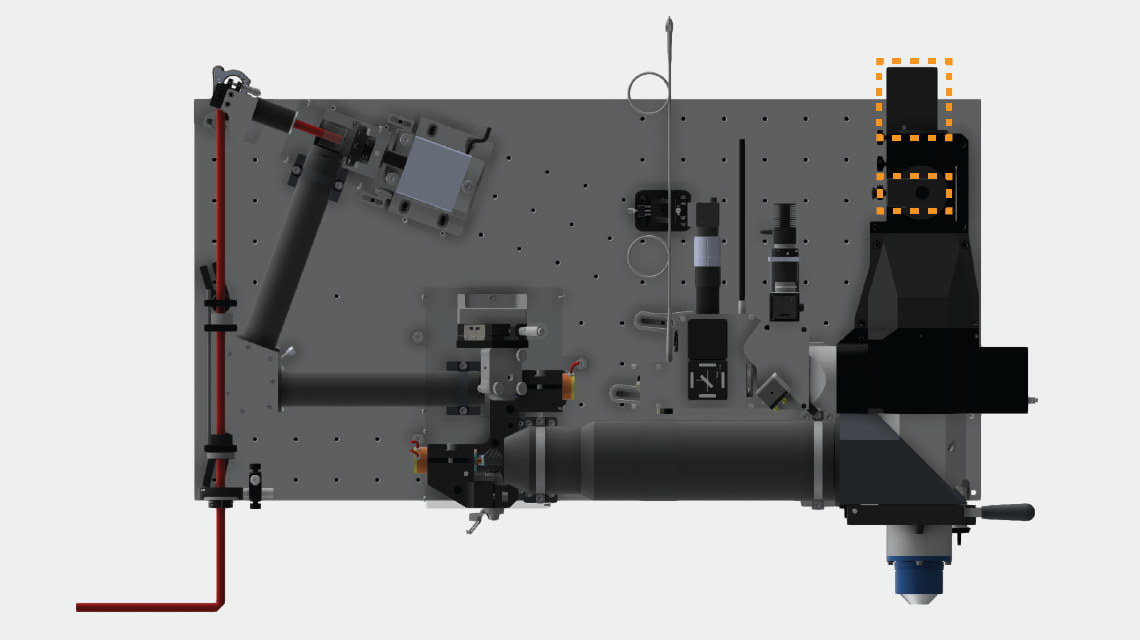

Model labels: DetChannelAssby:1, DetChannelAssby:2

Assembly instructions

PMT assemblyThe goal is to couple the lens onto the PMT face with oil

Seal the edge of the PMT face to the PMT housing with 5 min epoxy - careful not to soil the plate above the photocathode

Add 30 - 50 ul of high viscosity oil

Place condensor lens on oil. Make sure there are no bubbles and carefully remove overflow oil from the housing.

Place a thin ring of Kwik-Sil (WPI) on the PMT housing around the lens

Add PMTMountPlate before Kwik-Sil sets, such that sealant squishes between the lens and PMTMountPlate. Be sure that lens does not move up while mount plate is being pushed down. Allow ~30 minutes at least for Kwik-Sil to set (oil mixing with Kwik-Sil will interfere with the setting process).

Hold PMT in vise with window side down for several minutes to check if there is oil leakage. Blow gently around seal with canned air to see if there is movement of liquids/uncured Kwik-Sil.

If there is leakage, seal further between the condenser lens and PMTMountPlate using epoxy, or other sealant. It is OK if the sealant touches the face of the condenser lens a couple mm above where this lens meets the edge of the PMT mount plate.

Hold PMT at angle it will be used in microscope (depending on red or green channel) overnight, and check again that oil coverage between the condenser lens and PMT window is intact. There should be no obvious bubbles or inhomogeneities when looking at the photocathode through the condenser lens.

Alternate assembly technique, using UV cure, optical adhesive

(This technique has not yet been tried at Janelia. It would be wise to test the detection efficiency of your PMT before and after the procedure. The Hamamatsu factory has confirmed that "they do not expect the photocathode to be damaged by the UV light")

Place a few drops of UV cure adhesive to the plano face of the PMT condenser lens. Norland 61 or 81 may work OK. A more viscous adhesive such as Norland 63, 65, or 68 would be a better choice, as it would stay in the proper location better, and be a little more flexible once cured (perhaps making disassembly easier).

Insert condenser lens into PMT, check that UV cure adhesive fully fills the gap between the condenser lens and the PMT window (the photocathode, viewed through the condenser lens, should look uniformly black, with no obvious bubbles or inhomogeneities). Remove lens and add more UV cure adhesive if gap filling is not adequate.

Use UV cure light to cure adhesive through condenser lens. UV (365nm) transmission through lens should be >70%.

Add PMTMountPlate and attach to PMT with screws. Use judgement as to whether condenser lens should be attached to PMTMountPlate with epoxy to stabilize it.